Focus Products Group International delivers industrial product design to a large range of houseware manufacturers serving the kitchen, bathroom, retail and hospitality industries. With a focus on superior product design, the company started using 3D printing for prototypes some 6 years ago and had built a fast turn-around time to create prototypes for clients, usually about 1-2 weeks.

But the team felt that time lag was too long and turned to MasterGraphics, a provider of technology solutions and consulting for the manufacturing, building, civil and education industries. The team at MasterGraphics recommended the ProJet HD 3000 (now sold as the ProJet 3510 HD). This printer uses Multi-Jet Printing technologies from 3D Systems to print durable, precision plastic parts ideal for functional testing, design communication, rapid manufacturing and rapid tooling.

“The Projet Multi Jet Printer has been a terrific investment for Focus Products Group,” said Kevin Carr, Director of MasterGraphics Imaging Solutions, LLC. “They‘ve been able to speed up product development – putting a finished prototype in their customers’ hands in significantly less than time than their previous 3D printer –while reducing their prototyping costs.”

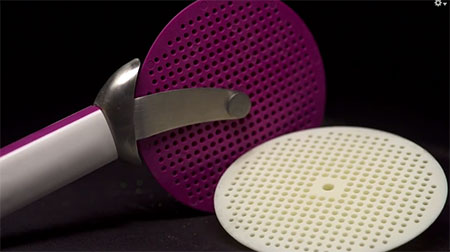

Click the image above to watch a comprehensive video which explains the process of design used by Focus Products Group while also outlining the decision-making process which drew the company to choose the ProJet 3D printers from 3D Systems.