Underwater camera case maker UK-GERMANY uses 3D scanning and Geomagic Design X reverse engineering technology to rapidly design new products.

The frigid waters of the Arctic Ocean are no match for the camera cases made by UK-GERMANY; nor are the salty depths of the Dead Sea. UK-GERMANY is a leading German company specializing in the development and manufacture of unique digital camera housing equipment for professional underwater photography. The company has been producing aluminum housings for cameras since 1990 and offers more than 60 types of underwater housings for both compact and DSLR cameras, whereby functionality and space savings are the main priorities. The cases are geometrically complex and are well known in the industry as being the leading choice for many outstanding underwater photographers because of their suitability for extreme operational conditions.

The digital camera industry has seen tremendous growth that has also brought about a shortening of model life spans. To stay on top of these rapid changes, UK-GERMANY turned to 3D scanning, reverse engineering and 3D printing. One example of the success of this work flow is a highly complex housing for the Hasselblad H3D camera made of polyamide plastic that is both watertight and pressure-proof to a depth of five metres. The company’s engineers needed to accurately capture the geometry of the camera to produce a well-fit camera case, resulting in superior underwater photography capabilities. A critical element to this workflow is the software used to create CAD models from 3D scan data. UK-GERMANY uses Geomagic Design X, a reverse engineering software that creates parametric CAD models directly from 3D scan data.

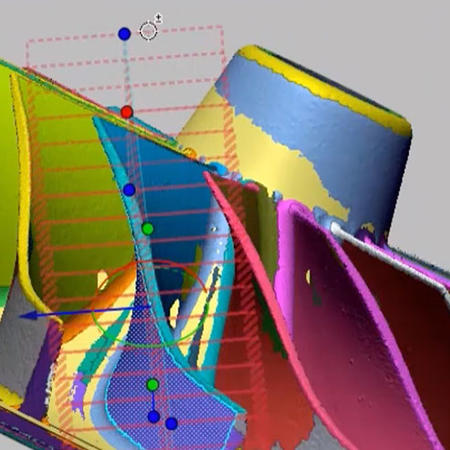

The team started by 3D scanning the entire Hasselblad H3D camera. With each scan, the scanner collects several hundred thousand measurements, ultimately forming a point cloud with several million data points that precisely indicates the location of various components of the camera.

A CAD solid model of the camera is needed to design the camera case, but regular CAD software cannot take advantage of all the information contained in the 3D scan data. CAD systems are built to handle surfaces and solids with defined dimensions such as radius and height – not the millions of individual points that make up the scan data. Then Geomagic Design X steps in. It combines point clouds and CAD models in one application, allowing 3D scan data to be leveraged in the design of new components. The model created in Design X is a parametric feature-based solid, with specific dimensions and constraints. UK-GERMANY’s engineers take the highly accurate CAD model of the camera and design a housing to fit it perfectly.

UK-GERMANY notes that using Geomagic Design X has cut the total processing time by more than 70% compared to the reverse engineering software they used previously. This efficiency saves time and money, and most importantly, brings products to market faster.