What makes a Ferrari, Lamborghini or Maserati so incredibly valued? These extraordinary sports cars are designed to excite all the senses with raw power, unique aesthetics, and exceptional handling. The right acoustics can also jumpstart the sensory overload craved by their owners and admirers alike.

Capristo Exhaust Systems GmbH is known worldwide for enhancing those emotions by perfecting the way high performance sports cars sound with personalized exhaust systems. However, the process of designing a new exhaust system around a very tightly packed sports car underbody is a painstaking task that used to take days. Since 2007, Capristo has been using 3D scanning technology to redesign exhaust systems faster and more precisely, in just a few hours.

Founded in 1989 by Antonio Capristo, Capristo Exhaust (www.capristoexhaust.com) has been designing and installing high performance exhaust systems almost entirely by hand. The team works with extremely high grade stainless steel pieces and turns them into works of underbody art in a 250 square meter workshop in the quiet town of Sundern, Germany. Their personalized aftermarket exhaust redesigns are best known for a unique roar that has been called “raw”, “aggressive”, and “priceless”. Not only do they improve the sound of the car, they increase horsepower and performance.

Capristo caters to owners of Italian, German and other exotic cars. For years, he was frustrated with one particular aspect of his business: the process of designing a new exhaust system that fits perfectly in each car’s existing underbody. Space in and under the vehicle is scarce, and his team often had to keep customers’ cars for hours or even days to remove the factory exhaust system and painstakingly measure the space it fits into. Even then, they would end up having to build a prototype exhaust system, install it, find problems, then hand modify or even scrap and rebuild it until the fit was right.

With the adoption of 3D laser scanning technology, Capristo can keep a customer’s car for less than an hour. Capristo remarked “It’s not only about the time savings – the precision and control that using the 3D scanner offers us are just as important.”

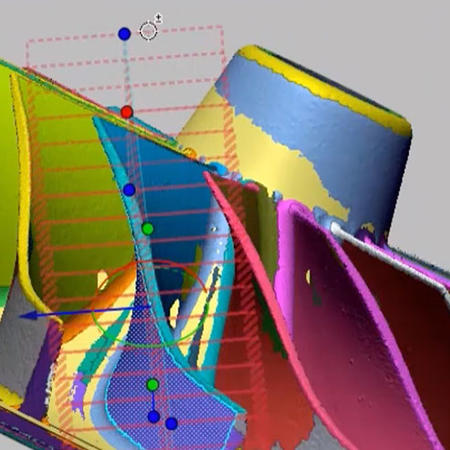

The team at Capristo starts by removing a car’s existing exhaust system and scanning the areas of the vehicle around it. With each scan, the scanner collects several hundred thousand measurements, ultimately forming a point cloud with several million data points that precisely indicates the location of various components under the car. This data is opened in a specialized reverse engineering software, Geomagic Design X, to create a polygon mesh model of the car’s underbody. It is from this virtual representation that Capristo can design a new exhaust system to fit a specific car.

This is where Design X comes into play. It combines the scan data and CAD models in one application, allowing the 3D scan data to be leveraged in the design of new components. The software allows Capristo to design the new exhaust system around the vehicle’s underbody. The model they create is a parametric CAD solid, with specific dimensions and constraints. It is identical to a design made in any modern CAD software, so the file from Design X can be used to program pipe bending equipment and CNCs to manufacture parts.

Capristo is state of the art engineering!

“Capristo is state of the art engineering!” raves SfefVan, a member of FerrariChat.com, the online Ferrari Community website. “Antonio Capristo is a brilliant guy, truly amazing! I’ve seen how the headers have been conceived and it’s an impressive part of true engineering. When you see how many industrial machines he has in his factory + a brilliant CAD engineer, you’ll understand.”

Capristo’s process is not about copying the existing exhaust design – it’s about making a completely new system with different air flow from the engine, around the underbody and out the back of the car. He has worked very hard to satisfy more than 15,000 customers in this super car niche market by improving both sound quality and performance of his personalized exhaust systems.

“We are saving hundreds of man hours each year using the 3D laser scanner and Geomagic Design X to scan cars and design new exhaust systems directly from the scan data, and we’re doing it more precisely and with higher customer satisfaction. Our customers don’t have to leave their cars with us, and we get the fit right the first time, which means that we recognized a 100% return on investment in the first year.” said Capristo.

Years of expertise and strong engineering skills, combined with 3D scanning technology, have determined the speed and accuracy at which Capristo can make his customers’ Prancing Horses sing.