Before the 2004 Olympics in Athens, the British Cycling Team found a unique way to help shave those precious fractions of a second: the team commissioned computational fluid dynamics (CFD) studies from the Sports Engineering Research Group (SERG) at the University of Sheffield to improve the overall aerodynamics of its equipment. A combination of Geomagic 3D reverse engineering software from 3D Systems, CFD programs from Fluent, and EnSight visualization software produced results that helped the team earn four medals.

Last-Minute CFD Analysis

In June 2004, just weeks before the Summer Olympics, the cycling governing body enacted a rule change stating that only helmets passing a formal safety test in an accredited laboratory could be used in Olympic track competition. The British Cycling Team had four helmet designs that fit the specifications, each with different aerodynamic stylings.

To help determine which helmet was best for competition, the team turned to SERG for a quick CFD analysis. The British Cycling Team had worked with SERG months before to optimize the aerodynamics of the handlebar and wheel/fork designs on the team bikes in preparation for the Olympics.

SERG's Dr. John Hart ruled out CAD as an option for creating the digital models needed for CFD analysis: there was not enough time to model from scratch, and CAD is not well-suited to create the organic shapes required for accurate modeling and CFD analysis of the helmets and athletes. Hart decided that the best solution was to capture the geometry of the athletes and helmets with 3D Scanners' ModelMaker X70 non-contact 3D laser fitted on a Faro Gold arm, then merge the scans and create a NURBS model of the data in Geomagic Wrap software.

“CAD engineers work at different tolerances than those required for CFD analysis,” Hart says. “Even if we had the CAD files for the helmets, we would have had to spend a great deal of time cleaning up the model to make it watertight. Reverse engineering the helmets and surfacing them in Geomagic Wrap guaranteed a highly detailed, watertight model in less time.”

Scanning the helmets was relatively straightforward. Each helmet took approximately 25 minutes to scan depending on the complexity of the design. The Faro arm moved around the object, capturing point-cloud data and depth information.

SERG planned to capture data from the athletes by scanning them in different racing positions; one aerodynamic posture and one where the cyclist has his or her head down to test more fully the effect of the helmet shapes.

Because of the time crunch, however, Hart did not have access to a cyclist; he had to scan a colleague for the human geometry. The subject was scanned over the course of two hours, allowing for rest breaks during the scan session. Completed scans were broken into sections that followed closely in succession – upper arm, lower arm, hand – to help eliminate issues from sudden movement during the process.

Refining Complex Scan Data

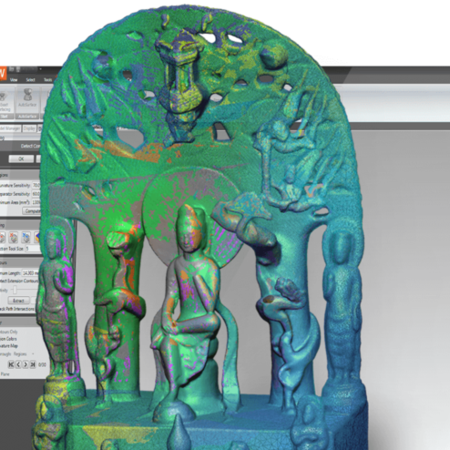

3D point-cloud data collected from the scans of the four different helmets was imported into Geomagic Wrap, a software used to enable reverse engineering to generate 3D models of physical parts for use in CFD analysis, design, retrofitting and custom manufacturing.

Geomagic Studio automatically aligned the scan data and a polygon mesh was applied. The model was cleaned to remove holes and defects in the data. Then patches were created over the polygons, outlining the positions of the NURBS surfaces.

Scan data from the human subject was handled in much the same way, except additional work had to be done to reduce noise and align the data due to subtle movement from Hart's colleague as he was being scanned.

Hart used Geomagic Wrap's point cloud ‘noise-reduction’ feature, as well as editing and filter tools, to refine the human model. He then used the product’s polygon geometric reconstruction functions to automatically fill in missing data such as body hair and eyebrows that weren't captured due to laser scatter.

“Geomagic Wrap's editing tools and ability to handle large, complex data sets made it a great match for this project,” says Hart. “We used the tools to refine scan data around the ears and in tight gaps, which enabled us to maintain a high degree of geometric realism on such a challenging human scan with nearly six million raw data points.”

Polygons and NURBS patches were applied to the human model and output by Geomagic Wrap as a STEP file.

“The STEP file format provides a robust geometric file that's not too large,” Hart says. “We can end up with a model with a large number of NURBS patches in order to capture the detail we need. The accuracy of the CFD study was highly dependent upon the geometrical accuracy of the assembled model.”