“F1™ is essentially a development race. Once the cars are on the track, that’s one thing, but every single week we’re trying to bring more performance to the car.” – Patrick Hawtin, Rapid Manufacturing Leader, Sahara Force India F1™ Team.

Revving Up Development

The pace of Formula One (F1™) development is rivaled only by the speeds achieved on the racetrack. Each time the Sahara Force India F1™ Team brings their car to a circuit, it represents the team’s top engineering; every time the team leaves, their car is just a baseline. Between races it must be re-optimized to out-perform the last, best version.

Sahara Force India F1™ is based in Silverstone and Brackley, United Kingdom, and has relied on 3D printing as a crucial component of its development process for over 17 years. Particularly useful for wind tunnel testing, 3D printing has saved Sahara Force India F1™ considerable time and money in the development and testing of new designs. Before 3D printing, not only was manufacturing more labor intensive, with pattern and composite shops providing tooling, carbon layering, curing, trimming and finishing, but the design process was also slower and more involved to accommodate these extra steps. Using the previous workflow, it took 5-7 days to produce one testable design. From a development standpoint where 20 or more iterations of a design are needed for testing, these traditional methods simply were not scalable.

Driving Innovation With In-House Productivity

“The benefits of using 3D printing in our design and development come down to cost, lead-time and quality,” said Patrick Hawtin, Rapid Manufacturing Leader, Sahara Force India F1™ Team. “3D printing gives us the capacity to make hundreds of parts in a week, and when we go through the wind tunnel testing, we do, there’s no way we could develop parts at the same rate without 3D printing unless we quadrupled the size of our more traditional manufacturing departments.”

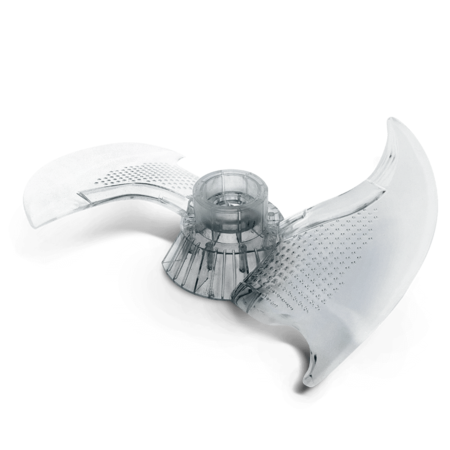

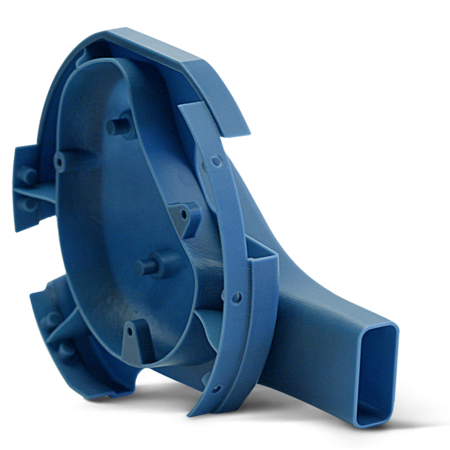

Sahara Force India F1™ predominately uses 3D Systems Stereolithography (SLA) for their wind tunnel tests. Hawtin says it is not just the throughput of the 3D Systems’ SLA printers that make them an asset, but also the accuracy and resolution of the systems to meet their target requirements. “3D Systems’ SLA systems deliver accuracy within a tenth of a millimeter,” Hawtin says.

Iterating in the Fast Lane

Sahara Force India F1™ Team’s Rapid Manufacturing Department works closely with the team’s Design, Aerodynamic and other manufacturing departments to devise new designs in multiple iterations. They use 3D Systems’ Stereolithography machines with a range of 3D Systems materials selected to meet their application requirements, including Accura® Bluestone, Accura Greystone and Accura 60. These applications include wind tunnel model parts, full-size parts, molds, cores and jigs. “We use SLA printing for airfoil sections and downforce testing, which require extremely smooth surfaces.” Hawtin adds that the temperature resistance of Accura Bluestone also makes it good for carbon molding.

“3D Systems’ SLA systems allow us to survey more and benefit from the sensitivity we can achieve with many iterations,” says Hawtin. “The amount of finesse we’re looking for would be lost if we did it any other way.”

Hawtin concludes, “The current pace of F1™ development would be pretty much nonexistent without 3D printing.”