One of the many facilities that use the Geomagic FreeForm system is the 3D Medical Applications Center at Walter Reed Army Medical Center, located in Washington, DC. The Center is the only one of its kind to serve DOD and VA hospitals countrywide. They create custom models and implants needed due to injury and disease-related problems.

The center’s director is Dr. Stephen Rouse, a retired military dentist, and the Senior Medical Engineer, Dr. Erge Edgu-Fry, is an atomic physicist by training. The two manufacture medical models primarily used for surgical planning. However, a considerable part of their work involves designing implants for soldiers wounded overseas. The demand for implants is high and the correct fit is critical. Dr. Stephen Rouse and Dr. Erge Edgu-Fry’s existing process included systems that could be hard to use and time-consuming where parts could take several days to model. They wanted a faster, easier (and therefore less costly) way to create custom implants that would also allow them to produce more refined parts.

The process to create a custom implant begins with CT and MRI scans. These systems produce “image slices”, which then need to be converted into a 3D model and then output as an STL file. In the case of a damaged skull, the Center can import STL skull data into a modeling software such as Geomagic FreeForm, and convert to virtual clay.

They then quickly create and manipulate an NURBS surface that encompasses the defect area and matches the curvature of the remaining skull and photographic images of the patient pre-injury. The NURBS surface is then thickened and converted to virtual clay. Using FreeForm's digital sculpting tools and Boolean operations, the original skull data is then used to remove geometry from the patch, resulting in a patch that fits perfectly at the beginning edge of the defect area. FreeForm digital carving and smoothing tools are used to remove any remaining undercuts on the back side of the patch, and to smooth the entire patch.

The picture on the left shows a damaged skull that has been fitted with an implant using Geomagic FreeForm. The scaled down version shows the skull prior to the implant being placed. For Dr. Edgu-Fry, this very example would have taken about 1-2 days with other software to model and with FreeForm, she was able to complete it in 2-3 hours.

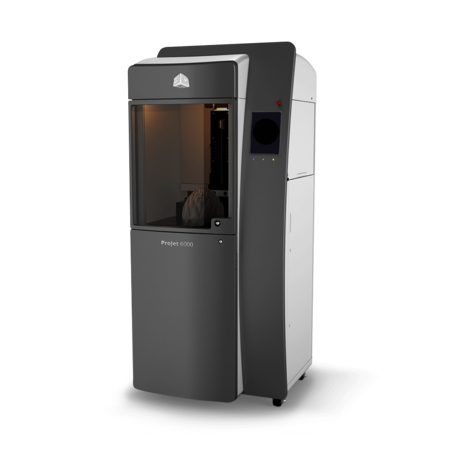

Once the model is completed, the doctors create a prototype (on a 3D Systems, Inc. SLA® 3D printer) made of epoxy resin. For implants, this prototype is then sent to a lab that uses the output to mold an implantable part, quite similar to the way dentures are made. Once this part has been completed the center either hand carries the part or sends it via overnight delivery depending on the hospital that ordered it.

Dr. Edgu-Fry first heard about FreeForm software at the end of July 2005. She received 6 hours of training on August 3 and received another 2 hours of training on August 24. As of September 15th, she is using the system daily and has completed prosthetic parts for 4 skulls, a couple of them already on their way for surgical implantation. Within 6 weeks and with 8 hours of training, she has become very productive and believes that tools like FreeForm are ideal for rapidly creating custom implants. Now that the doctors are becoming more proficient on the system, they have started to use its techniques to produce other types of projects, such as a pelvic implant that they are currently working on.

With FreeForm in the workflow, Dr. Rouse and Dr. Edgu-Fry estimate that it will take 2-5 hours per part, which is a significant time-savings over their existing method which can take 2 days or more to produce a hand-modeled implant. “Since using haptic devices with more effective software, such as FreeForm, is so easy, I’ve been able to complete implants for skulls faster and that are more refined than before. Now I can easily set whatever thicknesses I need and make smoother parts,” said Dr. Edgu-Fry.