"We're moving a lot faster, shaving weeks off our new product introduction cycles, and saving $3,000 per product in machining and moldmaking costs." – Chad Kroll, Product Development Engineer, Steeda Autosports

There are cars, and then there is the Mustang, the American icon of muscle. It’s a beautiful thing rolling off the assembly line, but many owners want to make it their own, make it better and, yes, make it even faster.

They often turn to Steeda Autosports, maker of the largest complete line of Ford based accessories. The Pompano Beach, Fla., USA, company’s product line ranges from stunning wheels to shocks and springs to chrome radiator caps. Then there are the products that enhance performance, such as the aftermarket Cold-Air-Intake Kit, which adds 60 HP to the 5-Liter 2011 Mustang GT.

Challenge

Prototyping Time and Expense

Aftermarket parts are a competitive industry and customers are price sensitive, so Steeda continuously investigates ways to extend its lead in innovation, quality and affordability. Recently, Steeda took a hard look at its prototyping process — mostly CNC machining — in search of ways to cut costs and increase speed. The prototypes were taking too long and costing too much, and they weren’t even realistic for organic shapes like molded tubes that needed to be tested in a wide range of sizes and configurations. “Machining these parts would have been outrageously difficult and expensive,” says Steeda Product Development Engineer Chad Kroll.

Strategy

3D Printing from CAD Designs

This examination led Steeda to 3D printing, a process that produces tangible physical models from 3D designs. Steeda looked at a range of rapid prototyping devices and selected a ProJet CJP 360, which offers fast, full color 3D printing for prototyping.

To create a concept prototype, Kroll’s team simply takes any CAD design — in their case, a SOLIDWORKS file — and sends it to the Color Jet printer (CJP) for production of a 3D physical model.

Results

Weeks and Thousands of Dollars Saved

“The 3D printed prototypes created are doing for our product development what our parts do for sports cars,” says Kroll. “We’re moving a lot faster, shaving weeks off our new product introduction cycles, and saving $3,000 per product in machining and mold-making costs.”

For parts like oil caps and hood pin plates, 3D printing replaces costly and time-consuming CNC machining of early prototypes, saving three days on each new product. For more organic shapes like the molded tubes in the cold-air intake kits, 3D printing makes it easy for Kroll’s team to test a wide range of sizes and shapes for performance and fit.

Prior to purchasing the 3D printer, Steeda engineers would repeatedly go back and forth with mold-makers revising mold designs until they settled on the final shape and fit.

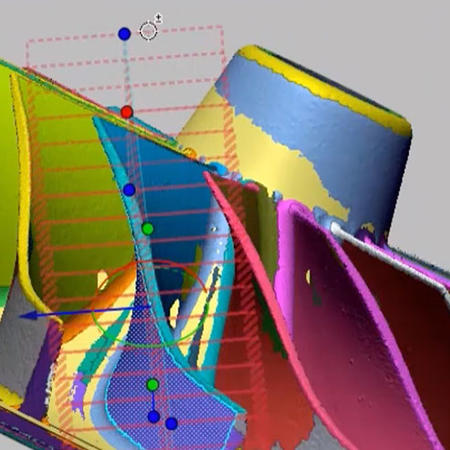

Now, when the design is done and ready for volume production, Kroll’s team simply provides the mold-maker with a final ProJet model. Instead of reading from plans, the mold-maker digitally scans the prototype using a 3D scanner and Geomagic Design X reverse engineering software and converts it into a mold. It’s always accurate on the first try. The new process saves time, money, and revision cycles.

Steeda occasionally bolts the ProJet parts directly to an engine, as with an airflow measurement device that helps Steeda make critical design decisions. Here again, the company saves time and money over molded or machined parts. Kroll’s team also uses the 3D printer to make prototypes to allow the sales force a preview of upcoming products, as with the company’s new line of Spyder wheels.

“In prototyping, moldmaking and marketing, 3D printing models is helping us work faster, more cost-effectively and more accurately,” says Kroll. “The 3D printer was a good decision for us, and it’s good for drivers of the Mustang. The ProJet just helps us develop a better-quality product.”