"The parts we received form Realize gave us an instrument so close to the real thing, customers thought they were already in production." - Scott Seelye

A staple in Hawaiian music, the ukulele’s name roughly translates as “jumping flea,” a tribute to the player’s fluttering fingers as they play the small, traditionally wooden instrument. It goes to say that given the busy, flea-like strumming involved, you can’t just make a “uke” out of anything. It’s got to be durable, and it’s got to sound good.

Outdoor Ukulele makes ukes designed for the outdoors, engineered for durability and tone so active uke enthusiasts around the world—backpackers, campers, mountaineers, sailors, students and more—can take them anywhere. When the company was perfecting its new tenor ukulele, they required the same durability in a quickly produced prototype. Enter Indiana rapid prototyping service provider and user of 3D Systems SLA machines, Realize Inc., which made a complete instrument for Outdoor Ukulele.

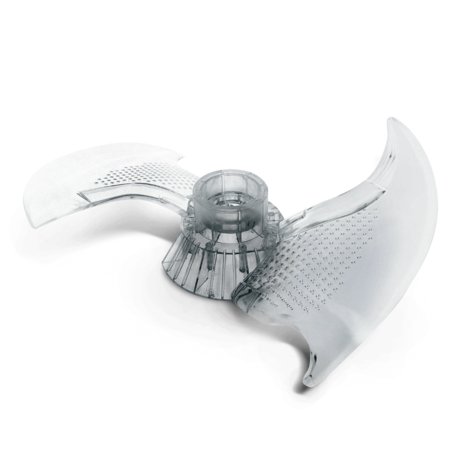

Realize Inc.’s project lead, Brian Cazzell, says that Outdoor Ukulele was having trouble finding someone who could build a full-scale prototype of its tenor ukulele using polycarbonate-like resin. The final instruments are injection-molded from glass-filled polycarbonate, and the prototype needed to be as close as possible in size and strength to the final instrument.

“Our biggest challenge with prototyping an instrument is receiving a part with the tolerances required to make it playable. The scale length and fret locations need to be exact,” said Outdoor Ukulele’s Scott Seelye. “Realize was the only company that was willing to attempt a part this size, which we would use as a working instrument.”

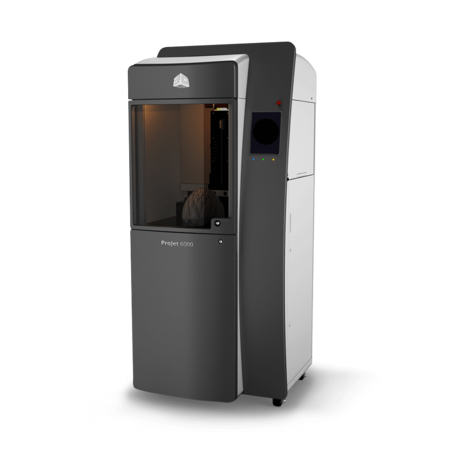

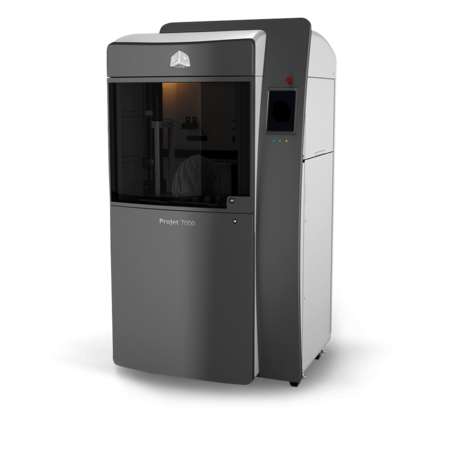

It was no problem for Realize Inc., which used 3D Systems Stereolithography (SLA) 3D printing and Accura® 60 resin to create the final prototype. SLA 3D printing is known for its superior accuracy, and 3D Systems has been perfecting the technology for over 30 years. The company’s founder, Chuck Hull, invented Stereolithography, and today’s 3DS SLA machines boast fast print times and large build volumes to complement the precision that the technology is known for. Today, aerospace, manufacturing, casting and medical modeling applications all go to the next level of speed and accuracy with 3D Systems SLA.

In this case, Realize Inc. was able to use the advantages of SLA to produce a working, playable ukulele prototype that fit Outdoor Ukulele’s exact specifications in only a few days. “The parts we received form Realize gave us an instrument so close to the real thing, customers thought they were already in production,” says Seelye.

Going forward, Outdoor Ukulele expects to use Realize Inc. as its only approved prototype company. “Our experience with Realize was wonderful,” says Seelye. 3D Systems is proud to have been a part of such a unique project, and happy to help service providers and manufacturing companies alike to create the parts they need more accurately and faster than ever.