Engineered Machined Products Inc. (EMP) of Escanaba, Mich., is the largest diesel pump manufacturer in the U.S. and one of the fastest growing manufacturing companies in Michigan. Its customers include diesel engine OEM giants such as Cummins, Caterpillar, Navistar, John Deere and Detroit Diesel.

“Our customers come to us, not so much with pump designs, but with specifications,” explains David Allen, vice president for product development and engineering. “We work off these specs to design, build and test pumps for them. Then we help bring the pump all the way into production.”

According to Allen, water pumps are surprisingly difficult to design correctly the first time. “Their workings usually feature extremely intricate geometries,” he says, “and even with the use of highly sophisticated analysis software and other tools, designing one that does exactly what you want it to do is tough.”

How They Used to Do It

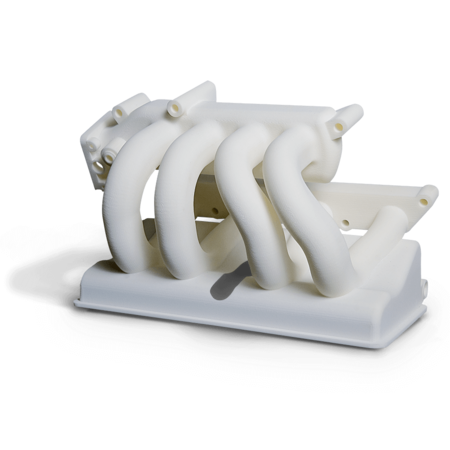

Pumps typically consist of two main components: a volute (an expanding, circular, horn-like chamber that directs the water) and an impeller (the complex, fan-like part that pushes the water). Prior to acquiring an SLS system, EMP ran the customer specs through its analysis software then ordered castings or made a CNC machined prototype of the complex pump design in-house. Typically, it would take six to eight weeks to acquire the necessary casting patterns, then another three to four weeks to acquire the actual castings.

“It would take about 10 weeks or longer just to get the pieces in,” Allen says. “Then we’d have to assemble and test them. That’s another six weeks.”

The costs so far: $100,000. But that’s not the really painful part. If the design doesn’t work, it’s back to the drawing board—and that adds up to more time and money.

A Faster, Less Costly Process

After seeing the benefits of the SLS system at an industry trade show and testing sample parts, EMP quickly acquired its own system to run DuraForm PA material, a strong, durable plastic

“Now, instead of going through pattern-making, casting and machining—a 16-week process—we can have prototype impellers and volutes made in a couple of days,” says Allen. “We can start testing right away. And if the design doesn’t work out, within another week or less, we’re testing another one.”

Allen emphasizes, “We estimate we’re saving 15 weeks and cutting our costs by 90% with each iteration, but time is what it’s all about. Paring our turnaround time down by 80% or 90% is just incredible for us and for our customers.”

Smarter use of valuable engineering talent

“Good engineering talent is a hot commodity today, as it should be,” says Allen, “and our SLS system has allowed us to better utilize the engineering resources we already have. This means we are more efficient and are able to have engineers spend more time solving problems for our customers.

“Our engineers now have the luxury and the desire to do more research and explore more designs. And if they make a mistake or a design doesn’t work out, it’s no big deal. It’s just a piece of plastic made on our SLS system, not an expensive casting. They fix the error, make another prototype, and move on. It’s not a big disaster.”

Allen adds, “We also have the opportunity to learn more about our products and how they work in real-world applications. It has had such a huge impact on our experience and knowledge of pump manufacturing.”

No More Panic Projects

One customer approached EMP recently with a project that had to be completed in just six weeks. With its SLS system at the ready, EMP tackled the project with ease and exceeded its customer’s expectations.

“We actually had enough time to design and test three different impellers and two volute variations,” Allen says. “Having a way to compress the prototyping cycle afforded us the time we needed.” Allen continues, “The customer was so happy—they ended up with a great product that met their specifications in just six weeks, as opposed to something that was just thrown together and delivered in 16 weeks.”

EMP has taken pumps from concept to testable pump even faster than that. Try just three weeks.

“We modeled the pump, ran it through analysis, modified it, prototyped it on the SLS system, assembled it, and tested it,” Allen recalls. “Customers come to us with projects like these because they know we’re probably one of the only companies that can do the work in time, and that’s a huge competitive advantage.”