What do Olympic Kayakers and 3D data have in common? The ability to make custom-fit shapes to allow kayak slalomers become world beaters.

Olympic sport keeps pushing athletes to find new and nuanced ways to condition their bodies. The same is true with their equipment. Engineers continually look for new refinements that propel the competition to a new level.

Olympic sport keeps pushing athletes to find new and nuanced ways to condition their bodies. The same is true with their equipment. Engineers continually look for new refinements that propel the competition to a new level.

In search of more success, the Australian Olympic Kayak team decided to turn to 3D technology to develop a better fitout' for kayakers in the canoe slalom. A fitout means building custom parts of foam and wood for the seat of the craft and a good fitout gives the competitors an especially crucial edge while they paddle through 18-25 gates as fast as possible.

Past methods of fitout have been laborious, mostly guesswork and a lot of wasted material. By turning to 3D scanning with Creaform and 3D model creation with Geomagic, the team has found a way to accurately create parts custom-fit to each athlete's unique body shape.

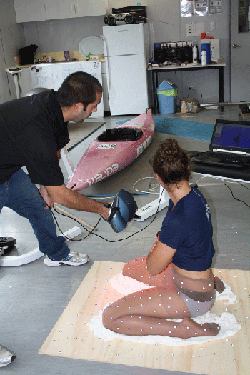

Each athlete was scanned in position using a Creaform 3D scanner. This accurately creates 3D points of the body surface, which are translated into 3D CAD models using Geomagic. From this point, the 3D can be precisely used to design and manufacture exact forms for the kayak - and for each athlete - to allow perfect control of the kayak from start to finish.

(Image above: Athlete Jessica Fox gets scanned by the Creaform REVscan prior to processing in Geomagic Studio.)

Read the full story at: https://www.geomagic.com/en/community/case-studies/kayak-slalom-presents-olympic-engineering-challenge/